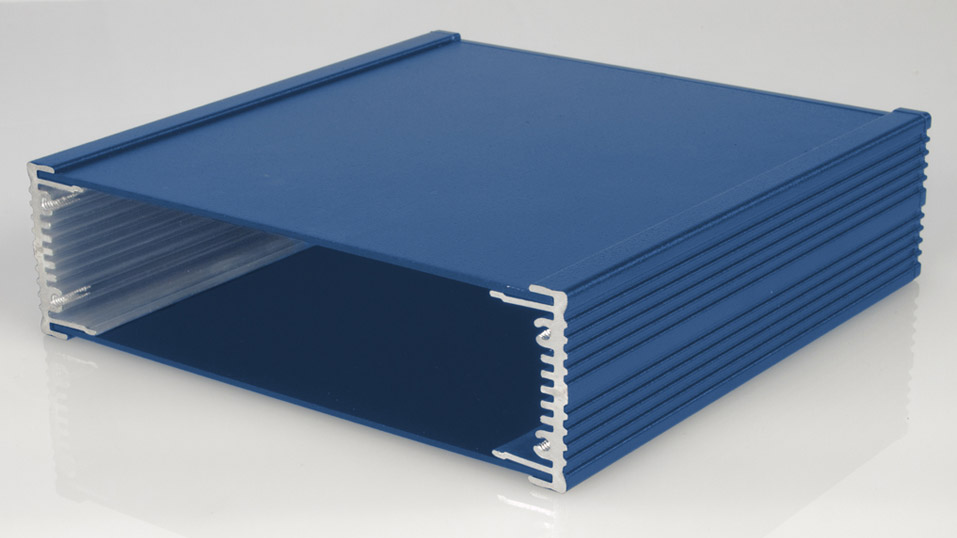

Description

Materials:

Our stocked extrusions are 6063 Aluminum.

Top and bottom panels specifically must be 0.064″ (mm) 5052 aluminum in order to fit the aluminum extrusion’s slots.

The front and rear panels in an extruded aluminum enclosure are also typically 5052 aluminum, though any of our stocked sheet metal may be used instead.

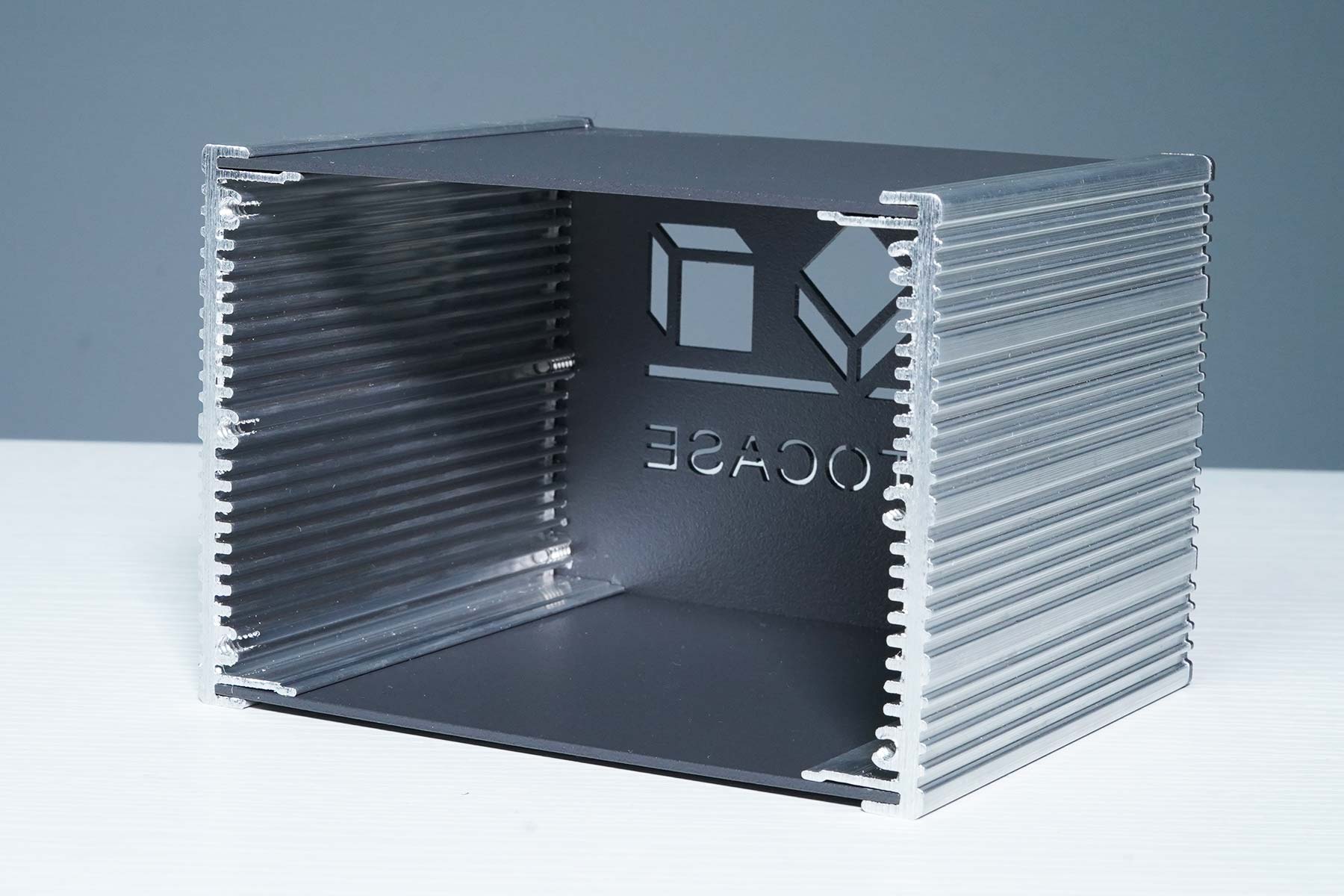

- → Type A – Contoured sides with top and bottom flanges

- → Type B – Straight sides with top and bottom flanges

- → Type C – Profiled sides with flush top and bottom

- → Type D – Straight sides with contoured top and bottom

- → Type E – Contoured sides with straight top and bottom

- → Type F – Straight side, top and bottom

You can mix the panel types to have different combinations, as well as make other customization to the panels. For instance, you can extend the sides of the front panel in order to mount the enclosure in a rack, or you can bend out the bottom flanges to use as mounting flanges for securing the enclosure in position.

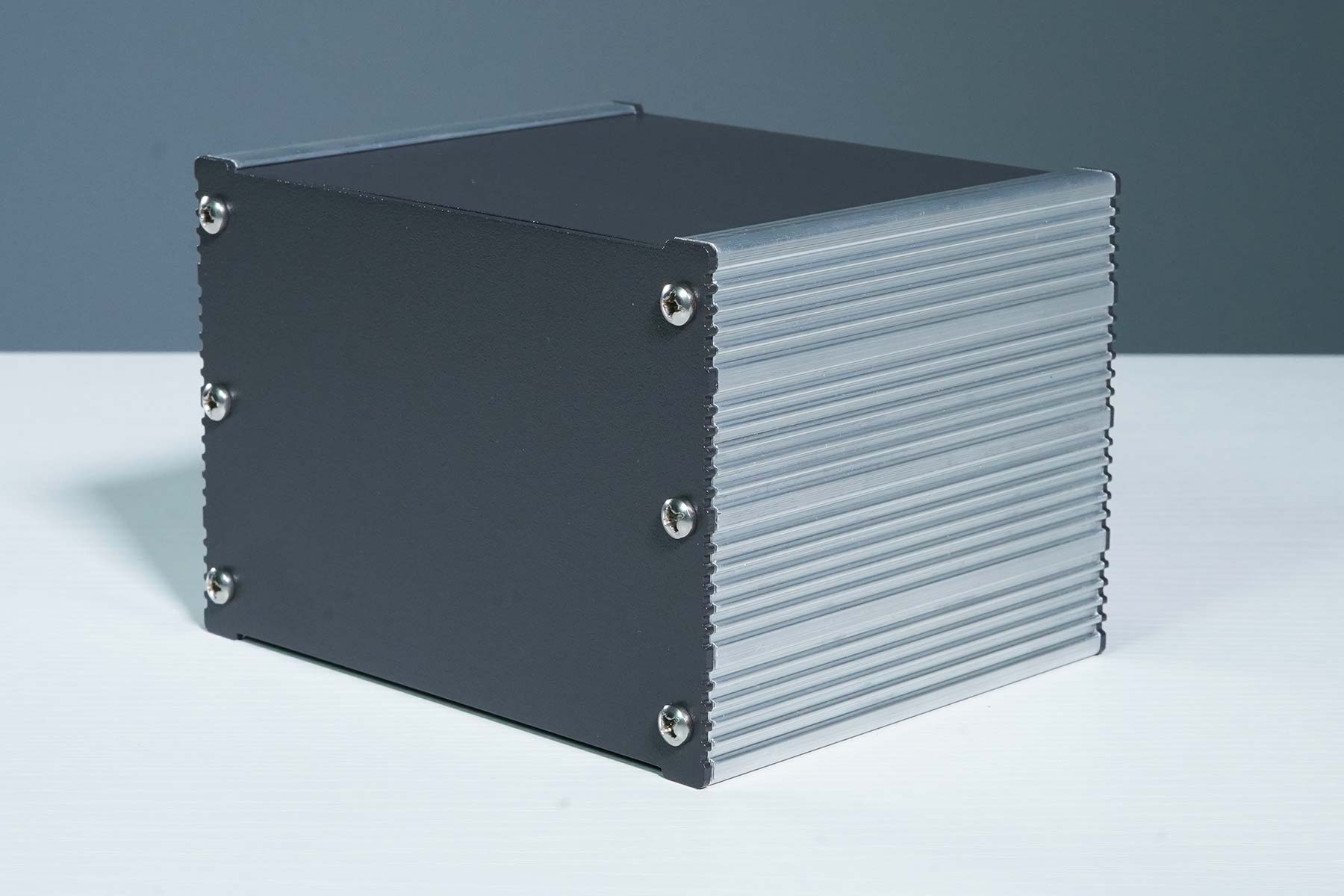

Fasteners:

We use #6 thread-forming screws for attaching the front and rear panels.

Self-clinching fasteners cannot be inserted into an aluminum extrusion unless a particular area on the extrusion is CNC machined first in order to insert the fasteners.

Fasteners can be installed in any of the enclosure’s panels, as long as the fastener doesn’t interfere with the extrusion once the enclosure is assembled.

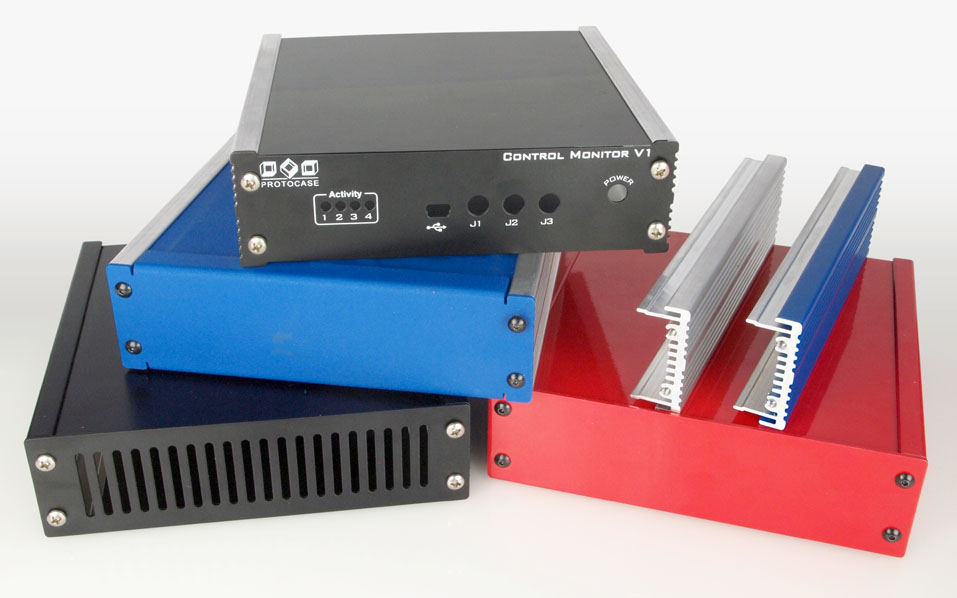

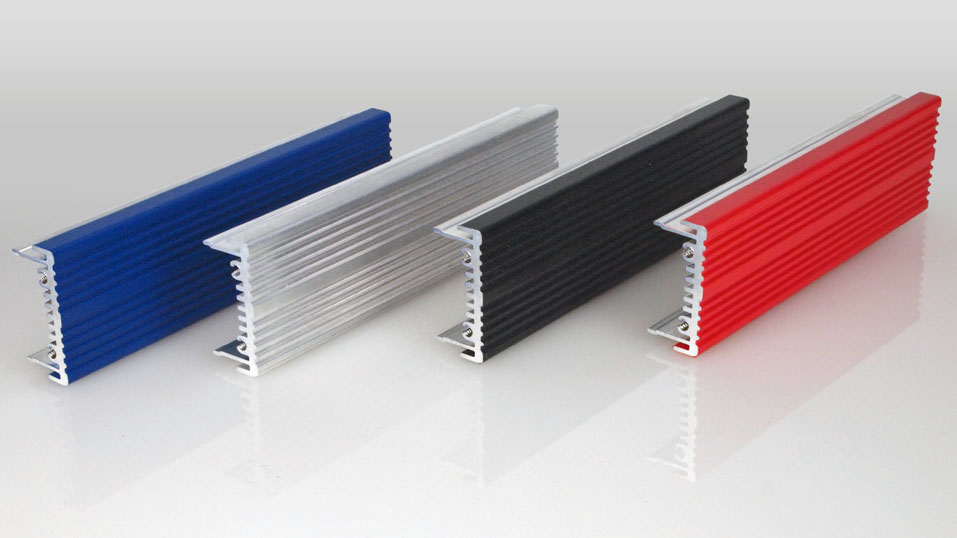

Finishes:

The aluminum extrusions (side rails) come in a bare aluminum mill finish. Powdercoat and/or chem filmed can be applied to the extrusion as a secondary finish. We do not recommend applying anodizing to aluminum extrusions.

The panels in an extruded aluminum enclosure can have many of our finishes applied (either for all four panels, or part-by-part):

- Powdercoat

- Chem-Film Coating

- Anodizing*

- Grained Finish

- Vibratory Finish

- Masking

Graphics & Permanent Marking:

The panels in an extruded aluminum enclosure can have graphics and other marking applied:

- Digital Printing

- Silkscreening

- Machined Engraving

- Dot Peening

Key Dimensions:

| 1U Extruded Enclosure | 2U Extruded Enclosure | |

|---|---|---|

| External Height | 1.72″ | 43.688 mm | 3.47″ | 88.138 mm |

| Internal Height | 1.443″ | 36.6mm | 3.194″ | 81.1mm |

| Maximum Length | 35.0″ | 889.0mm | 35.0″ | 889.0mm |

| Maximum Width | 23.0″ | 584.2mm | 23.0″ | 584.2mm |

| Minimum Length | 2.0″ | 50.8mm | 2.0″ | 50.8mm |

| Minimum Width | 1.625″ | 41.275mm | 1.625″ | 41.275mm |

We are happy to provide custom or non-stock extrusion profiles for additional charges and an extended lead time.